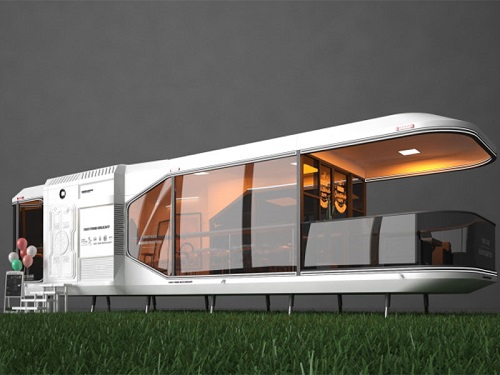

In the era of rapid urbanization, environmental concerns, and evolving lifestyles, housing is no longer restricted to permanent concrete structures. A new frontier in architecture and engineering has emerged—the Portable Prefabricated Space Capsule House. This concept merges aerospace-inspired design, modular prefabrication, and sustainable technologies into a versatile solution for modern living, off-grid survival, and even extraterrestrial exploration.

1. Introduction to Space Capsule Housing

A space capsule house is a compact, modular unit inspired by aerospace engineering, designed to resemble the aerodynamic shape of a space capsule. Unlike traditional prefabricated homes, capsule houses emphasize mobility, compactness, and high structural integrity, making them ideal for temporary yet comfortable habitation.

2. Structural Design and Engineering Considerations

2.1 Shape and Aerodynamics

The capsule shape is not only aesthetic but also functional.

It provides:

- Wind resistance: The curved structure reduces drag, enabling stability in extreme weather.

- Load distribution: Evenly disperses structural stress across the shell, minimizing weak points.

- Thermal efficiency: Curved walls reduce thermal bridging and improve insulation performance.

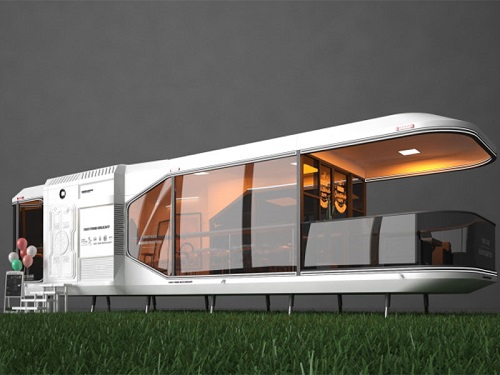

2.2 Materials

- Outer Shell: Often composed of fiber-reinforced composites (FRP), aluminum alloys, or steel frames combined with insulating polyurethane foam panels.

- Interior Panels: Lightweight yet durable materials such as high-pressure laminates, recycled composites, or bamboo panels for eco-friendliness.

- Windows: Triple-glazed, low-emissivity (Low-E) glass with UV coatings.

The goal is to balance lightweight portability with high strength, while also ensuring fire resistance, corrosion resistance, and long-term durability.

2.3 Prefabrication Techniques

Portable capsule houses are manufactured off-site in controlled factory environments.

The main methods include:

- 3D Modular Printing: For walls and shell segments using concrete or polymers.

- Steel Frame Prefabrication: Lightweight frames assembled with bolted connections.

- Flat-pack System: Components that can be folded or disassembled for transport.

Prefabrication ensures precise tolerances, reduced waste, and faster assembly times compared to conventional construction.

3. Portability and Deployment

3.1 Transportation

Portable capsule houses are designed to be shipped via:

- Flatbed trucks for short-distance transport.

- Shipping containers for international logistics.

- Helicopters or drones for remote or disaster-struck areas.

The units are typically light enough to be lifted by cranes and compact enough to fit in standardized ISO container dimensions.

3.2 Assembly

Most capsule houses are designed for rapid deployment:

- Basic units can be assembled within hours by 2–4 workers.

- Modular systems allow interconnection of multiple capsules to form larger habitats (e.g., community clusters, research bases).

- Plug-and-play systems for utilities (water, power, HVAC) enable quick operational readiness.

4. Energy and Sustainability Systems

4.1 Power Supply

- Solar Panels: Integrated on curved surfaces or deployable fold-out wings.

- Battery Storage: Lithium-ion or next-generation solid-state batteries for off-grid autonomy.

- Hybrid Generators: Backup systems using hydrogen fuel cells or biodiesel.

4.2 Water Management

- Rainwater Harvesting Systems: Collect and purify water through multi-stage filters.

- Greywater Recycling: Reuse of shower and sink water for irrigation or toilet flushing.

- Compact Desalination Units: For coastal or island applications.

4.3 Thermal and Environmental Control

- HVAC Systems: Compact, energy-efficient air circulation and purification systems.

- Passive Insulation: Vacuum-insulated panels or aerogels minimize heat loss.

- Smart Ventilation: Heat recovery ventilation (HRV) systems reduce energy consumption.

The Portable Prefabricated Space Capsule House represents a paradigm shift in how humans approach living environments. By merging aerospace design, modular construction, and sustainability principles, these capsule houses transcend traditional architecture and open possibilities for resilient, adaptable, and futuristic living.

As technology progresses, capsule houses could become not only a solution to global housing crises but also a critical stepping stone for humanity’s ventures into outer space.